Our Sustainability Commitment

Sustainability at Wolf-Gordon

Guided by the holistic approach to sustainability presented by the Common Materials Framework and the AIA Materials Pledge, we work closely with our partner mills to improve our products and practices with both wellness and the environment in mind.

-

The Wolf-Gordon product line is constantly growing and evolving. Products are frequently added to and, occasionally, discontinued from our line. For this reason, the product percentages given in this document are conditional and approximate; phrasing such as “more than 50% of our Type II wallcoverings” indicates that the precise figure may fluctuate.

-

NSF/ANSI 342 is a third-party certified, multi-attribute sustainability standard developed by the Wallcoverings Association. It was designed to evaluate and certify the sustainability of wallcovering products across their entire life cycle. NSF/ANSI 342 was developed in 2008 with the American National Standards Institute (ANSI), an accredited third-party certification body that tests products to verify that they meet the established standard. NSF/ANSI 342 is undergoing revision in 2024-25 to accommodate evolving expectations of sustainability, including human health and wellness factors. Wolf-Gordon is NSF/ANSI 342 certified as a distributor.

Wolf-Gordon Walls

Health, Climate, and Our Ecosystem

-

Environmental Product Declarations (EPDs) are our industry’s standard for disclosing the materials that make up products. Most information on the EPD is easy to identify and report on, but there are three elements that make their completion and maintenance challenging for our partner mills: lengthy supply chains that involve multiple stages of raw materials suppliers, ever-evolving raw materials suppliers, and full calculation of the carbon expenditure number.

As a designer and distributor of wall finishes, Wolf-Gordon’s goal is to be as accurate as possible in our reporting. More than 50% of our Type II wallcoverings have third-party certified EPDs and we continue working toward 100% availability of this detailed reporting vehicle.

-

All of our wall products meet the CDPH (California Department of Public Health) Standard Method for VOC emissions (CA 01350). Over the past several decades, all heavy metals and hazardous phthalates have been eliminated.

Printing and embossing are the processes that make our wall products beautiful. Mills print our wallcoverings and wall protection—RAMPART and RAMPART Resolve®—with extremely safe inks, which are recycled in a closed-loop system to minimize waste. Water utilized in the process is treated on-site to ensure below local effluent discharge limits prior to release into the local municipal collection systems. Printing processes are regulated by the Federal EPA, The Clean Air and Water Acts, OSHA, and state regulations.

-

Wolf-Gordon was first to market with two essential PVC-free alternatives that meet the high-performance standards of their vinyl counterparts: CLAIR® Type II wallcoverings (2020) and RAMPART Resolve® wall protection (2022). Both CLAIR and Resolve are collections that we continue to expand as long-term commitments.

-

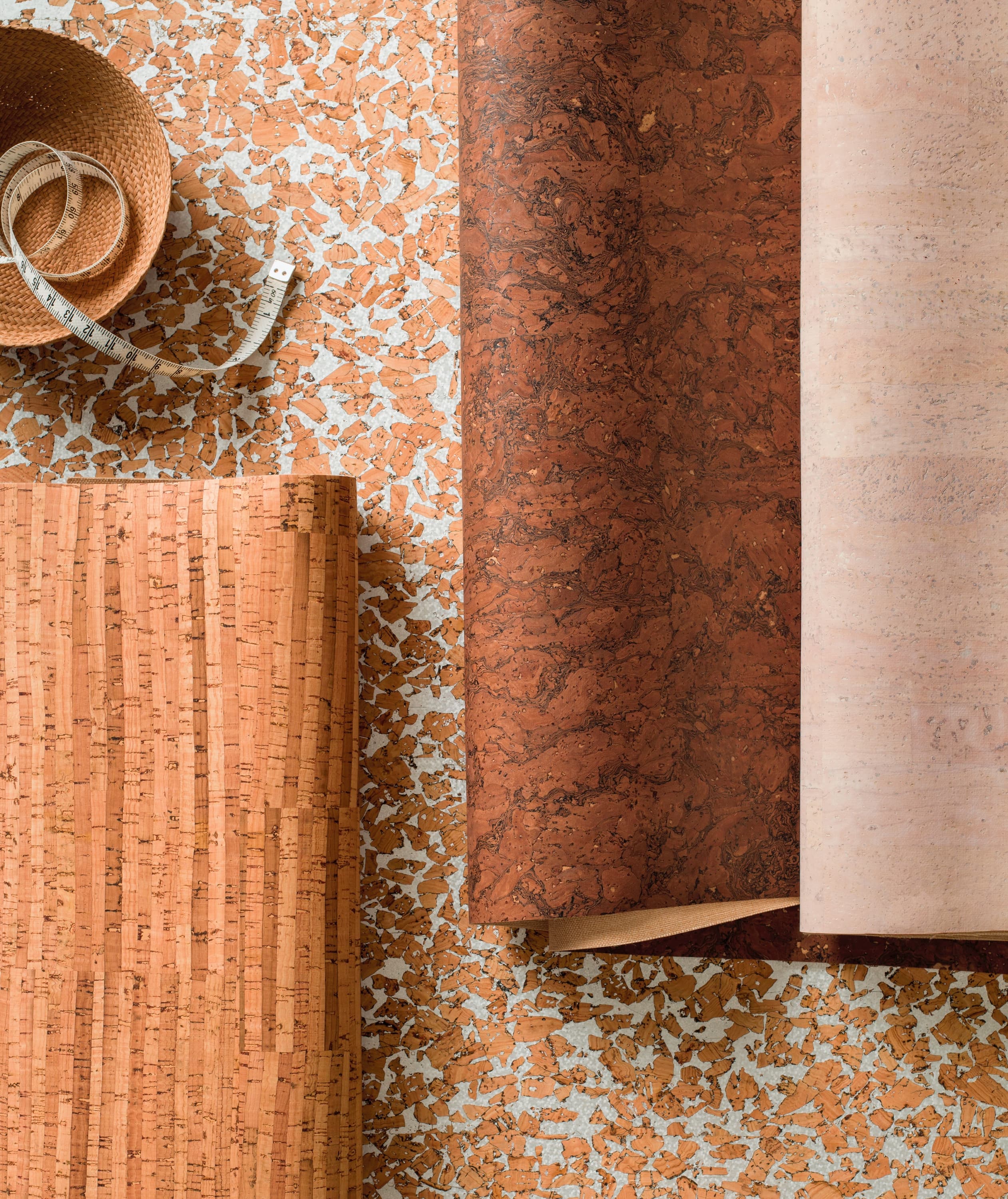

Since our founding in 1967, we have offered natural wallcoverings as integral to our line. Natural wallcoverings are manufactured from low-impact resources such as grasses, paper, and natural fibers. Our popular wood veneer and cork wallcoverings are made of renewable and biodegradable wood sourced from responsibly managed forests. FSC documentation is available for many species.

-

We also offer several products manufactured in whole or in part from recycled materials. For example, GATHER® Acoustical panels and Felted acoustical wallcoverings are made of 100% recycled PET.

-

While contract wallcovering has several potential sustainability assets, including a low-emissions production process* and durability that prevents the need for frequent touching-up or replacement, it poses significant end-of-life challenges, specifically regarding recycling. After its use, wallcovering products are almost always contaminated with other, non-recyclable building materials. Furthermore, the recycling of wallcoverings for downstream use has not yet proven its economic viability. The Wallcoverings Association is in the pilot stage of a potential solution for this problem, and Wolf-Gordon supports this initiative.

-

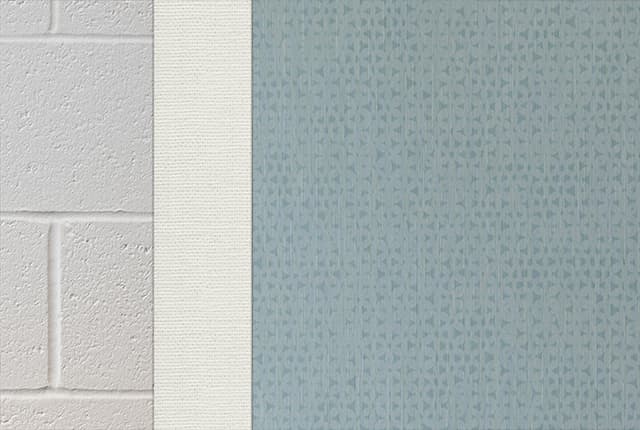

RAMPART Stronghold® wall liner enables the prolonged utility of existing walls and finishes by creating a smooth surface for applying RAMPART. Stronghold, which is made of low-impact jute and gypsum, is easily applied over existing walls and wall finishes (pre-existing drywall, tile, CMUs, rigid wall panels, etc.), avoiding their demolition, removal, and disposal to landfills. RAMPART provides the final, decorative, protective layer for high traffic interiors.

-

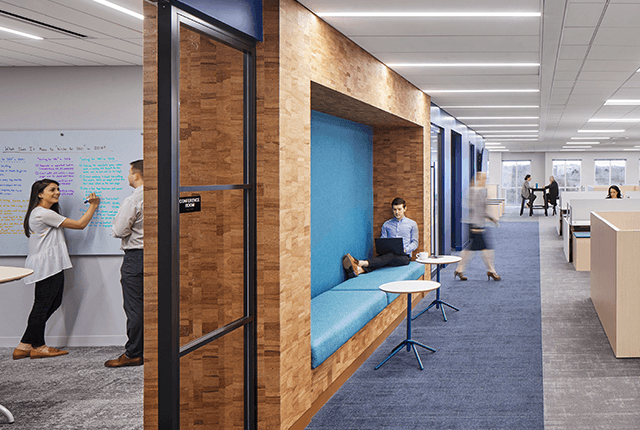

Our wall products include a wide range of resilient, high-performance interior finishes that require less frequent touch-ups or need for replacement. Our contract and PVC-free Type II wallcoverings are made using relatively low-impact processes*, and their ability to withstand high traffic interiors means that they will not need to be frequently discarded and replaced. RAMPART and RAMPART Resolve® flexible wall protection provides beautiful design that protects walls from heavy abuse. Our Scuffmaster® line of paints provides superior stain- and scratch-resistance with industry-leading scrub ratings, ensuring that walls can withstand commercial cleaning protocols and require repainting much less frequently.

Human Health and Social Equity

Focusing on Human Health

- We have been compiling Health Product Declarations (HPDs) for our products for over a decade. We now have HPDs for the vast majority of our Type II wallcoverings and all of our Scuffmaster paint, RAMPART wall protection, and GATHER Acoustical products.

- All our Type II, Acoustical, Cork, and Wood wallcoverings, RAMPART, and paint products meet the CDPH Standard Method (Cal 01350) for VOC Emissions and are listed in the mindful MATERIALS library.

- Our GATHER Acoustical materials are Declare certified and comply with the global Oeko-Tex Standard 100.

… and Social Equity

Wolf-Gordon’s interior finishes are 100% free of conflict minerals. “Conflict minerals” include tantalum, tin, tungsten and gold, mined in politically unstable areas by forced laborers.

The location of manufacture is important. Products made in the United States are subject to our strict labor and environmental regulations. All of our Type II wallcoverings and wall protection, including PVC-free CLAIR and RAMPART Resolve, are made in the USA, as are all of our Scuffmaster paint finishes.

Our suppliers, regardless of country of operation, are required to complete a Supplier Agreement, which details minimum working ages, wage and hour labor laws, hiring discrimination policies, and environmental health and safety policies. For products manufactured abroad, such as our textile wallcoverings, we secure further documentation attesting to the supplier’s monitoring of these issues. We refuse to do business with non-compliant suppliers.

Our Carbon Pledge

Wolf-Gordon has pledged to be carbon neutral by 2050 in accordance with the 2015 Paris Climate Accords. We have chosen this date because it provides a realistic timeframe for Wolf-Gordon to make our operations carbon-neutral. A more immediate goal would practically require corner-cutting measures such as the purchase of carbon offsets, which have been shown to be an ineffective approach amounting to greenwashing. In 2023, we took our first steps towards our net-zero goal via a comprehensive third-party audit of our company’s carbon footprint. Currently, we are working with our partner mills to compile metrics on carbon used in the manufacture of our products. Once all relevant data is collected, we will use it to create a stepped plan for yearly progress towards our goal.

Wolf-Gordon Upholstery

-

More than a third of our upholstery textiles contain recycled content that ranges between 10% and 100%. We need to keep in mind, however, that recycled content might contain trace substances that are now excluded from products. Like much of the discourse around sustainability, we critically evaluate the upside and downside of each strategy.

-

The contents of textiles need to be safe for the health of the people who make them and the people who use them. One hundred percent of our upholstery textiles are free of flame retardants.

-

Older generation stain resistant treatments (developed prior to legislation passed in 2022) contained chemicals called PFAS, otherwise referred to as “forever chemicals”. These older SR treatments were effective against oil-based stains but were hazardous to the environment and would never break down into benign substances.

Newer SR treatments do not contain long-chain PFAS, but are only effective on water-based stains, which means that they are no more effective than mild soap and water. According to a study published by LaPier et al. (2023) of the Green Science Policy Institute in the AATCC Journal of Research, non-treated textiles perform approximately as well as SR-treated textiles subjected to moderate wear.

Wolf-Gordon aims to educate specifiers on these facts and encourage them to do their own thoughtful research. In our view, the fewer chemicals we include in our products—especially those that are only marginally effective—the better.

Sustainable Products

Above all, Wolf-Gordon prides itself on being an innovative American design company. We develop beautiful products that serve the aesthetic and performance needs of our specifiers while being conscious of selecting materials that are safe and beneficial to humans and the environment. This desire to create innovative interior products has led us to pioneer several alternative, and more sustainable, wall and upholstery materials.

We were first to market with a PVC-free contract wallcovering that meets or exceeds all Type II performance standards. The Best of NeoCon Gold CLAIR® collection offers a growing array of unique patterns, textures, and colorways, which are bleach cleanable.

To complement our popular RAMPART® wall protection, RAMPART Resolve® is a PVC-free alternative that meets the performance standards of rigid sheet goods. It’s flexible enough to wrap corners, impact- and stain-resistant, and easy to install and clean.

RAMPART Stronghold®, a wall liner made of natural jute and gypsum, transforms irregular surfaces such as CMU into smooth walls for applying RAMPART, eliminating the need to demolish and remove existing wall substrates that would otherwise be sent to landfills.

One of the most sustainable natural materials, our cork wallcovering and upholstery textiles are made from cork bark that regenerates. Processed without chemicals, the hypo-allergenic and mildew-resistant material is high-performing and has the feel of soft leather.

Made in the USA, our wood veneer wallcoverings are constructed with lumber harvested from sustainably managed forests, and conform to the requirements of the Healthier Hospitals Initiative . Prefinished panels in a wide range of species are available and FSC traceable on request.